Perfume is more than a fragrance. It’s an experience, a lifestyle, and often a work of art. Luxury perfume brands have invested heavily in bottle design for decades to reflect elegance, creativity, and exclusivity. However, a new wave of innovation is transforming the industry: 3D technology.

From 3D modelling and rendering to 3D printing of prototypes and final packaging, this technology is giving brands unprecedented freedom to experiment with design, materials, and customisation. The result? Perfume bottles that are not only beautiful but also sustainable, functional, and deeply personal.

If you’re curious about the broader impact of packaging design, we also recommend reading: How Perfume Bottle Design Shapes User Experience.

Why Perfume Bottle Design Matters

Before diving into technology, let’s remember why packaging is so important in the fragrance industry:

- First impression: The bottle often influences purchase decisions before customers even test the scent.

- Brand identity: A perfume bottle tells the brand’s story, whether classic, modern, bold, or minimal.

- Emotional connection: Packaging creates desire and makes the product collectable.

With competition growing in the luxury and niche perfume markets, brands need unique packaging to stand out. This is where 3D technology becomes a game-changer.

For a deeper dive into visual identity, see the complete guide to perfume branding.

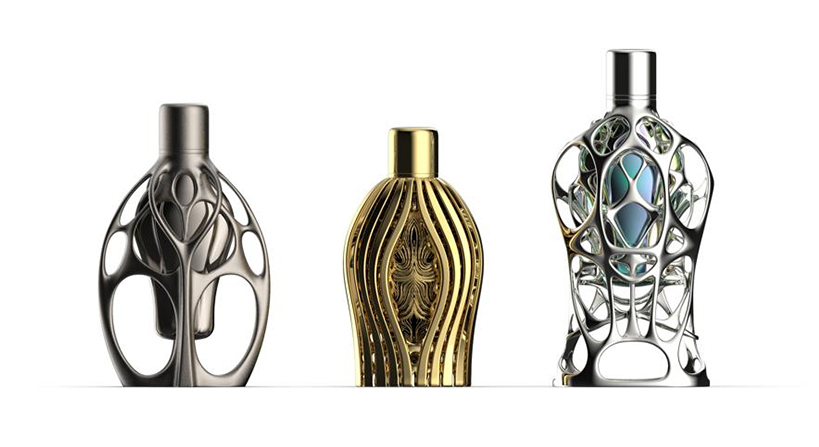

The Impact of 3D Printing on Perfume Bottle Creativity and Function

3D printing is opening new possibilities in perfume bottle design. Designers can create detailed shapes, experiment with textures, make personalised bottles, and use eco-friendly materials.

These five points show how 3D technology is changing perfume bottles, making them more creative, functional, personal, and sustainable.

1. 3D Modelling for Creative Freedom

Traditionally, designers relied on sketches and hand-carved moulds. Today, 3D modelling software allows them to visualise and refine designs in a digital environment.

Benefits include:

- Exploring complex geometries like asymmetry, spirals, and hollow patterns.

- Testing textures such as matte, frosted, or embossed surfaces.

- Simulating glass, plastic, or metal finishes before production.

This reduces risk and speeds up the creative process, letting brands experiment without heavy upfront costs.

2. Rapid Prototyping with 3D Printing

One of the most disruptive changes is rapid prototyping. With 3D printers, a design can move from concept to a physical sample in hours instead of weeks.

- Speed: Designers can test multiple bottle shapes, sizes, and closures quickly.

- Accuracy: Every detail, from the curve of the neck to the engraving on the cap, can be evaluated.

- Cost-efficiency: Eliminates expensive mould production for early-stage testing.

This agility helps brands respond to market trends faster, reducing time-to-market for new perfume launches.

If you’d like to explore how shape affects fragrance perception, check out this blog: Different Shapes of Glass Perfume Bottles and Why They Matter.

3. Customisation and Personalisation

Modern consumers seek products that feel personal. With 3D technology, brands can offer:

- Limited editions with exclusive shapes or engravings.

- Personalised bottles featuring customer initials, messages, or symbols.

- Collaborations with artists to create collectable designs.

This shift toward experiential luxury enhances brand loyalty while making perfume bottles feel like one-of-a-kind treasures.

4. Sustainable Perfume Packaging with 3D Printing

Sustainability is no longer optional. It is now an expectation. 3D technology supports eco-friendly packaging by:

- Using biodegradable or recyclable 3D-printing materials.

- Creating lightweight bottle structures that require less glass or plastic.

- Allowing brands to test refillable systems and modular designs.

By reducing waste and energy during production, brands align with green values while maintaining luxury aesthetics.

5. Enhancing Storytelling Through Design

Perfume is an emotional product, and the bottle should reflect its story. With 3D tools, brands can create narrative-driven designs:

- Nature-inspired: Floral shapes, crystal-like facets, or ocean-wave textures.

- Futuristic styles: Geometric, abstract, or space-age-inspired structures.

- Cultural symbolism: Designs that echo heritage, traditions, or artistic movements.

By embracing these expressive design directions, brands can forge meaningful and lasting impressions with their audience.

Real-World Examples of 3D Technology in Perfume Packaging

Some pioneering brands are already embracing this shift:

- Carolina Herrera has experimented with sculptural bottle concepts using 3D visualisation.

- Cartier and Bulgari have used 3D prototyping for jewellery-inspired perfume bottles.

- Niche fragrance houses are adopting 3D printing to produce small-batch artisan bottles that stand apart from mass-market designs.

These examples highlight how both luxury giants and indie brands can benefit from the same technological toolkit.

Future of Perfume Bottle Design with 3D Innovation

As 3D printing materials evolve, from bio-based plastics to high-quality glass composites, the possibilities for perfume packaging will continue to grow. In the near future, we could see:

- On-demand production reduces inventory waste.

- AI-assisted 3D design, combining consumer data with design creativity.

- Smart bottles, integrating QR codes or NFC tags into 3D-printed structures for interactive experiences.

Perfume packaging will no longer be limited by manufacturing constraints but shaped by pure creativity and innovation.

Final Thoughts

3D technology has evolved beyond a mere design instrument. It is igniting a creative transformation in perfume packaging. By blending artistic innovation with eco-friendly practices and tailored experiences, it empowers brands to craft bottles that captivate the eye, resonate emotionally, and align with sustainable values.

At Olila Package, we understand that packaging is more than protection. It is brand storytelling. With advanced design expertise and innovative solutions, we help perfume brands create packaging that captures attention, builds loyalty, and elevates the fragrance experience.